Shipping

Ask about this product

Program

Performance

Freeride

Speed

Foil

Technical Specifications

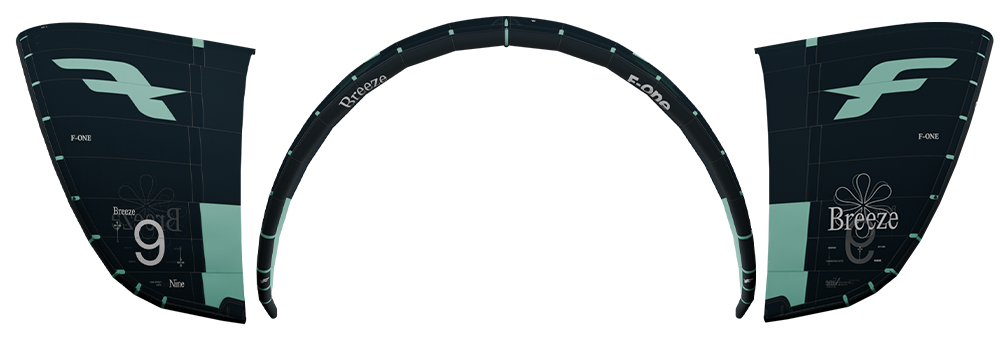

New outline and design for improved performances

Thanks to the new outline, new shape of the wingtips as well as our patented Delta C-Shape, this fifth BREEZE offers an easier relaunch and increases accessibility in the low end.

The relaunch and reverse launch processes have been further simplified by reducing the aspect ratio and optimizing the outline. The new profile also guarantees natural upwind abilities and increased stability, even in the most difficult conditions.

The stability of the BREEZE at 12 has also been significantly improved, ensuring comfort in both light and strong winds. The kite’s repositioning in the wind window guarantees constant traction, facilitating take-offs in the low end and upwind tacks.

Most of the BREEZE’s inflatable structure remains in HITEX 158g. This high tenacity polyester offers great resistance to elongation and therefore greater durability and performances. The wingtips are made of Dacron 150g to guarantee lightness and comfort. The central strut is stiffer thanks to the use of HITEX, making it even easier to keep the kite’s shape and to relaunch if it falls in the water.

The kite’s canopy is now made of TECHNOFORCE™/D2 52g, and the trailing edge of the thicker TECHNOFORCE™/D2 66g. The materials are perfectly distributed to account for the different tensions, high pressures, and weight distribution in each specific area.

Finally, the addition of another Staggered Seams panel on the trailing edge minimizes deformations, ensuring an impeccable profile and maximum performance. We have optimized the fabric’s orientation towards tension as well to ensure a smooth transition between the two TECHNOFORCE materials.

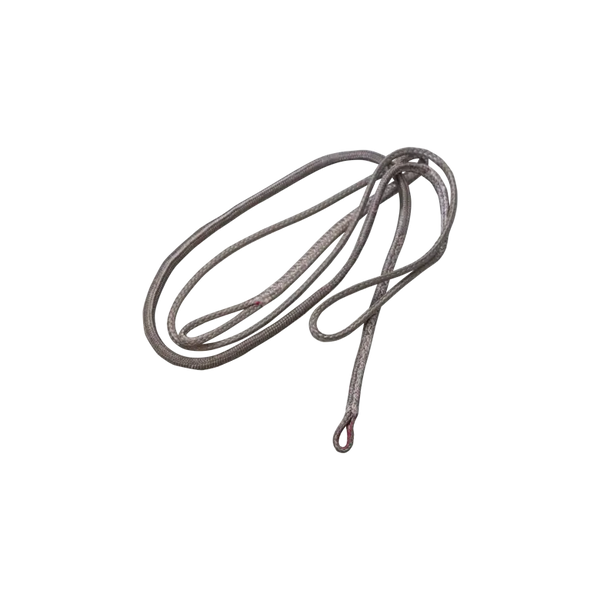

Optimized bridles

The bridles have been redesigned to guarantee maximum control of the deformations and of the profile of this one-strut kite, providing optimal comfort when riding and intuitive handling.

Its design, benefiting from a low-V setup, optimized tension distribution and new durable and efficient low-friction pulleys, offers optimal airflow and exceptional in-flight stability.

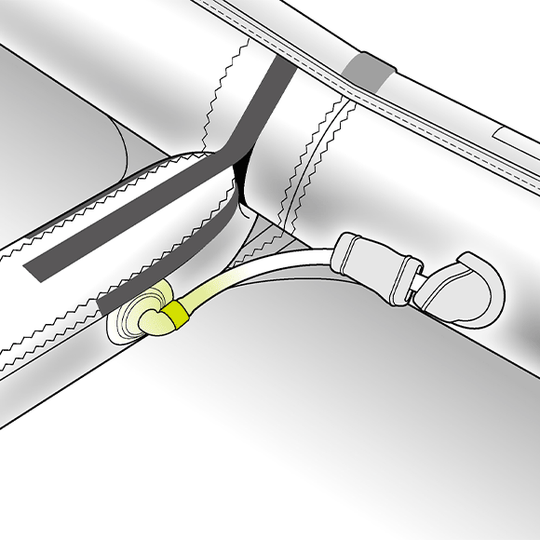

An area of 60cm in the main V is interchangeable, allowing you to replace only the worn friction zone without having to change the entire bridle system. This zone is the same on all surfaces, making it even more so a clear plus for schools.

Exceptional versatility

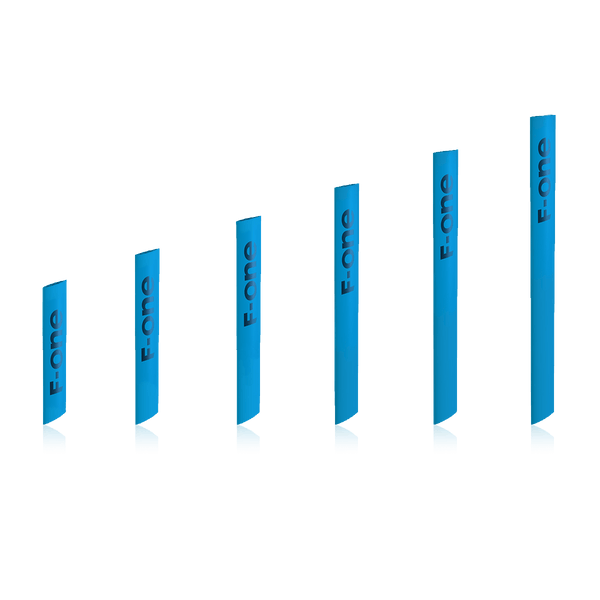

The new BREEZE stands out for its remarkable versatility, and is for anyone wanting a lightweight setup that offers amazing maneuverability with great performance abilities in the low-end. Thanks to our range of sizes from 7 m² to 17 m², the BREEZE is suitable for all levels, for freeride and foil enthusiasts, and for those who love light wind sessions.

It also offers an easy lift to get started on jumps, and boasts impressive responsiveness while remaining easy to control. In the air, the BREEZE is extremely intuitive; you can forget about your kite and fully concentrate on your ride.

Finally, this kite features a new one-pump valve with a larger diameter for quick and easy inflation.

Versatile, responsive, and easy to control, this new BREEZE is the best choice for light wind kiteboarding.

DELTA C-SHAPE

DELTA C-SHAPE technology design offers unmatched stability and steering response when fully de-powered, with the possibility of connecting the front lines higher on the leading edge of the kite.

DELTA C-SHAPE is a patented design used by F-ONE on all kites for the past 15 years.

This shape was the result of a design research towards maximum optimization of the aerodynamic performances of the kite and of its depower. It gives the possibility to fit more canopy area in the middle sections to create more projected area while the C Shape makes sure the kite remains responsive and fluid.

REACTOR VALVE

The reactor inflation valve offers a high flow connection that twist locks the pump hose to the kite for an easy and super-fast inflation and deflation at the push of a button.

It provides a high air flow rate between the struts and leading edge.

AUTO RELAUNCH

F-ONE’s auto relaunch is quick and easy and releases the kite from the water with the perfect amount of traction.

Once the kite is sitting with the leading edge flat on the water, its C-Shape associated with the Delta Pivot allows the kite to automatically roll over onto one wing tip.

The kite will then glide towards the edge of the window, ready for quick and easy water relaunch.

STAGGERED SEAMS

This brand-new F-ONE's design innovation offers an amazingly sleeked profile for more efficiency and sharper performances.

Original staggered seams have been implemented on critical parts of the kites. The seam’s tension line is broken offering a perfectly leveled canopy profile when the kite is fully powered.

The fabric is orientated towards tension. The perfectly even canopy profile brings a sensational stability without feeling disturbances in the bar.

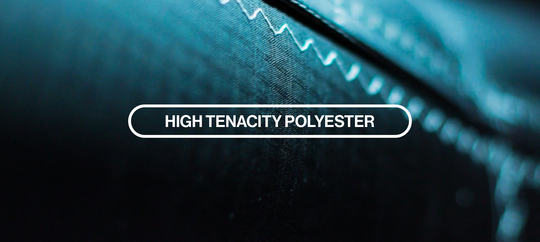

HITEX

To meet the specific needs of the development of wings and kites, and to offer a high-performance and durable product without using inaccessible materials, F-ONE has developed HITEX, a new high tenacity polyester. Available in 158g, and exclusively for F-ONE in 178g, this new material is incredibly resistant to elongation and increases the durability of wings and kites.

HITEX is an innovative, high tenacity polyester fiber with an enhanced high-quality weaving and coating that increases the fabrics’ resistance. The 178g is a new weight and perfectly matches the needs of the center strut and center of its leading edge. The lighter 158g is used in the leading edge tips.

Used throughout the inflatable structure of the wings and kites and designed to handle the high pressures when inflating, HITEX offers performance and resistance. Thanks to extensive Sail Engineering work, the R&D team has placed each weight of HITEX in different areas allowing absolute control of the shape session after session.

TECHNOFORCE

TEIJIN’s TECHNOFORCE™ is the most reliable high density polyester fabric. Its tear-stopping structure using thin and high tension yarn makes the fabric ultra-durable.

It has a great proven track record of lightness and durability.

SAIL ENGINEERING

Sail engineering is the science of controlling our design and its behavior while flying. These features have been created with one goal in mind: Mastering the kite’s loads to maintain the desired shape for the longest time.

1 – WARP TENSION LINE

Woven fabrics feature a longitudinal 0° yarn (Warp) and a transversal 90° yarn (Weft). Therefore, a fabric has great elongation resistance and strength capacities if you apply tension at 0° or 90° along the yarns. But it will deform and stretch when tension is applied at, let’s say, 45°.

2 – LOAD CONTROL PANELING

When engineering the load control paneling, we make sure that fabrics panels are warp/weft oriented, meaning that the load path runs through the yarns. Fabric and seams are then in the best position to receive tensions and maintain the original kite shape.

3 – STAGGERED SEAMS

Most of the kite’s back lines tension is distributed through the trailing-edge panels and seams. As seams are significantly stiffer than the fabric they join, they tend to strain under loads and therefore deform the profile. The staggered seams break that line of tension by balancing the stiffness between seams and cloth, which helps distribute the load over a wider area and maintain the original shape even under high loads.

4 – FABRIC WEIGHT MANAGEMENT

Our sails feature four different cloth weights, from 52 up to 155gr/m². Sail engineering allows us to control our shape and drive load tensions without using heavy fabrics or bulky designs, therefore we can reduce fabric’s weight and use. It results in a lighter, optimized kite.

BACK LINE TUNING

How to adjust the settings?

SHEETED IN The back line is released and the forces go through the front connector. The bar pressure increases and the maneuvrability is less direct. It offers a very progressive bar with a feeling of a sheeted out back connector while we sheet in, therefore the pressure increases progressively.

SHEETED OUT The kite tilts and the back line stiffens. The tensions move to the trailing edge which has several effects: - less flapping - better start - maneuvrability with less pressure.

HIGH TENSION TUNING When the kite is sheeted out with the upper knot tuning (1): -kite’s maneuvrability increases -bar pressure reduces

LOW TENSION TUNING When the kite is sheeted in with the lower knot tuning (2): - kite’s maneuvrability reduces - bar pressure increases

FLAT SEWING

Stronger assembly of the panels: they are now glued and sewn together to make the canopy more rip resistant.

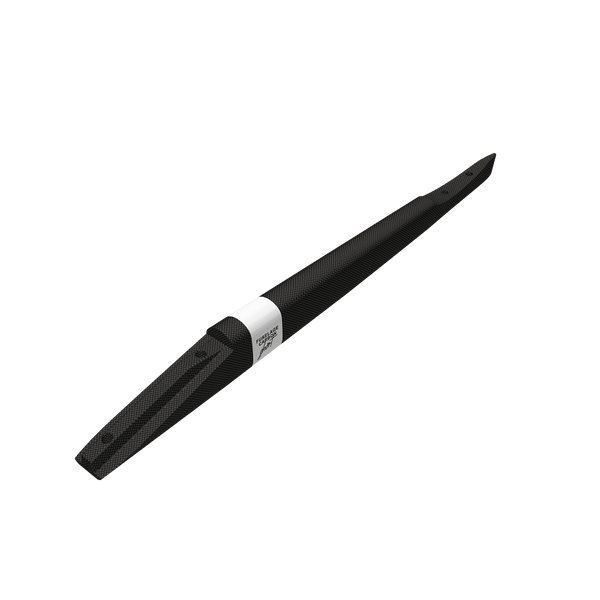

STREAMLINED LEADING EDGE END TIPS

The leading edge tips benefit from a reduced diameter, they are streamlined to lower the drag and equipped with a strap to avoid bridle tangling

ONE PUMP COLLAR VALVE

Easier to remove and put back. Convenient for bladder replacement.

SPIDER BRIDLE

The Spider Bridle is a multi-point of connection well dispatched along the leading edge which offers a better control of the arc of the kite during the flight. The stability in all wind conditions is very impressive and pushes the high wind range to incredible limits.

| SIZE (m2) | 7 | 8 | 9 | 10 | 11 | 12 | 14 |

|

Weight in kg (kite only) |

2,28 | 2,48 | 2,68 | 2,89 | 3,05 | 3,26 | 3,62 |

| WIND RANGE (knts) | 25+ | 20 > 35 | 15 > 30 | 12 > 26 | 11 > 24 | 10 > 22 | 08 > 18 |

| Bar size (cm) | 45/38 | 45/38 | 45/38 | 45/38 | 52/45 | 52/45 | 52/45 |